The waterproof breathable membrane is a kind of high molecular waterproof breathable material. The common ones we often encounter include PE waterproof breathable membrane, PP waterproof breathable membrane, TPU waterproof breathable membrane, e-PTFE waterproof breathable membrane, etc. Today, let's talk about the production process of waterproof breathable membranes.

Currently, the production processes of waterproof breathable membranes in the world are mainly divided into two types:

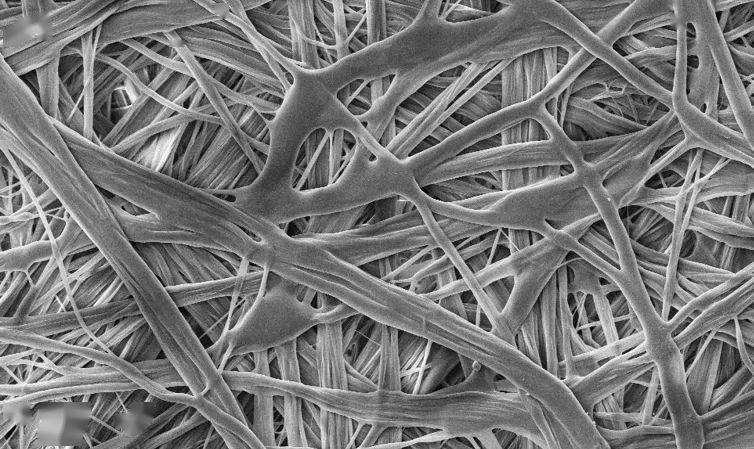

The first type is the flash evaporation method non-woven fabric

The flash evaporation method is to dissolve the polymer in a high-pressure solvent to form a homogeneous solution, then spray it out through a nozzle under high temperature and high pressure conditions, causing the solvent to vaporize instantly (flash evaporation), and the polymer is subsequently precipitated and forms extremely fine continuous fiber nets. Finally, it undergoes processes such as bonding and drying to be made into non-woven fabric. This production technology was previously only able to be produced by DuPont Company, and the technology was monopolized. However, now factories in China have also broken through this production technology, and the product technical parameters although cannot be exactly the same as those of DuPont Company's products, the similarity has reached 90%. Such products have high tensile strength and tear strength, good gas and water vapor permeability, are difficult for liquids to penetrate, have tolerance to various chemicals, and are easy to print. They are widely used in fields such as building waterproof breathable membranes, protective clothing, packaging materials, filtering materials, labels and printing substrates.

The second type is waterproof breathable composite membrane

The waterproof breathable composite membrane usually selects waterproof breathable membrane and PP or PET materials for compounding. Currently, there are three production processes, namely, extrusion compounding, spray glue or scrape glue compounding (also known as hot melt glue compounding), and hot press compounding.

1. Extrusion compounding

The extrusion compounding process is to use plastic pellets to heat melt and then compounding by relying on the plastic's own adhesiveness. After compounding, it is almost non-permeable. For waterproof breathable composite membranes that need to be permeable, this process is not very applicable, so as of 2014, no country in the world has used this process to compound waterproof breathable membranes!

2. Spray glue or scrape glue compounding (hot melt glue compounding)

The spray glue process was first applied to PE waterproof breathable membrane compounding, such as sanitary products, diapers and protective clothing. In the field of building waterproof breathable membranes, the membrane material can be sprayed with glue, and during construction, it can be directly attached to the front or roof.

3. Hot press compounding

The hot press compounding process has high permeability, high temperature resistance, and a static water pressure of over 2 meters. It is a pure heat compounding technology, without glue, so it can reach a temperature of over 110 degrees Celsius, high strength. It is also the most accepted production process in the market at present.

HYFabric can currently produce all types of waterproof breathable membranes mentioned above, can accept various specifications and brands for customization, and can provide customers with samples that meet their requirements. If you are interested in this type of product, please contact us.